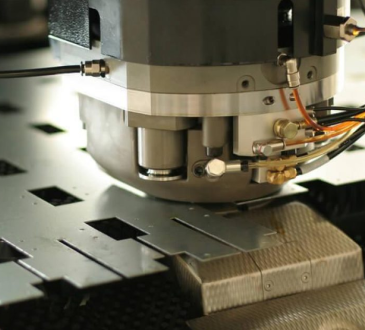

Welcoming a New Era in the Industrial World with the Next Generation Control Valves. This will usher in a new era of control valves that will introduce unprecedented precision, efficiency, and variability to various applications associated with the management of fluid and gas flows within different industries. This article will expose to light the key advantages and functionalities of these advanced control valves, such as 9422csf50.

Key Advancements:

- Smart Technology Integration: The new generation of control valves are the smart technology part that forms integral members positioned in the industrial Internet Of Things (IoT) system. Such valves incorporate sensors and connectivity for ongoing measurement, remote operation, and access to information required for guiding decisions.

- Enhanced Precision and Control: Some of the advantages are, that these control valves offer an unprecedented level of precision and achievement. They are intended to deliver the right” flow rate on a steady basis for quality products, minimize waste, and enhance process efficiency.

- Predictive Maintenance: Say goodbye to unplanned downtime. The next-gen control valves’ predictive maintenance applies prediction analytics and machine learning forecasting for possible problems that may develop necessitating timely planned maintenance that will save on waiting time, and reduce operational costs.

- Adaptive Control Algorithms: This phenomenon is made possible by the use of adaptive control algorithms that help the valves scale down in line with ever-changing process variations. This is beneficial for peak performance in dynamic environments and avoiding manual intervention.

- Energy Efficiency and Sustainability: Sustainability a Top Priority in Control Valves Next Generation. These are designed to decrease power consumption and environmental emissions so that the industries can meet the requirements of their environmental policies as well as minimize impacts on global warming.

- Digital Twin Technology: The use of digital twin technology in simulating and scrutinizing valve performance is enabling this. This helps in identifying and solving problems before affecting operations ensuring continued productivity.

- Improved Materials and Durability: The future control valves are manufactured with the latest materials and coatings rendering them more durable and reified to corrosion. In other words, these switches will be more durable and their maintenance costs will be low.

- Remote Monitoring and Control: One can do this valve management remotely, a feature that makes operations on the valves more flexible and unnecessary for others to reside at the site. This is particularly good for industries that operate in a decentralized manner.

- Cybersecurity Measures: Strong protection against cyber threats of more digitally connected control valves helps to guarantee the safety and security of industrial processes, particularly at times when these are threatened.

- Industry 4.0 Integration: The new generation control valve is merged with the industry 4.0-ready technologies to form connected, smart systems for optimal production processes and resource utilization.

Please visit website, if you are looking for modern smart control valves.