The fast life of the 21st century demands better results with limited imputes. This is the result of Westernization, which is rapidly taking over us. However, as humans evolve with every passing day, their lifestyles, needs, and priorities also tend to be the same. Therefore, industries and factories also have to work twice as fast as their usual capacity to keep up with the demands of the fast lifestyle.

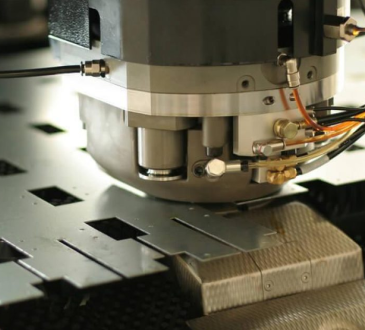

However, occasionally, machinery has to be upgraded to ensure better functioning and efficient working. Various components go into making complex machinery. However, with time, discoveries and modern inventions take up this space, replacing the old parts and mechanisms. But Ball screw (บอลสกรู BLK, which is a term in Thai) has been unchanged and unmoved even after so much evolution. It is a highly effective mechanical part that is employed in various machinery. In this article, we will discuss the benefits of installing ball screws in modern-day machinery.

What Are The Advantages Of Using Ball Screw In Modre Machinery?

· Versatility In Application

Ball screws are versatile in application that can be installed in various machinery across different industries. Ball screws are employed in multiple machineries to enhance their productivity and enhance the functionality of their machinery. The reliability and adaptability of this machinery make it an ideal choice for engineers and designers for linear motion solutions.

· High Load Capacity

Ball screws are specially designed to handle heavy loads and function in extreme situations. The use of ball screws is mainly used in heavy-duty industries like automobile manufacturing, where it is important to have swift and precise movement of heavy machinery. The ability to withstand heavy loads makes ball screws an ideal choice of ball screw for heavy machinery.

· Reducing Friction

Ball screws promote linear motion and reduce friction significantly. This is an important factor that contributes to the use of ball screws in intricate machinery where movement is more frequent. The rolling component between the ball bearing and screw threads helps in reducing the friction significantly, thus ensuring smooth movements of heavy-duty machinery.

· Sustainability And Efficiency

Ball screws are effectively used in heavy machines to promote efficiency and effective movement. However, due to heavy usage, these machinery often tend to wear out very easily, but if your machinery has a ball crew installed within it, this results in enhanced efficiency and better service of the machinery. Moreover, as industries lean towards sustainability and environmentally friendly functioning, the impact of ball screws becomes even more significant.

· Better Movement

Ball bearings are popular for promoting linear motion and enhancing the precision of your machinery’s movement. Ball screws recede friction and enhance the rolling motion of your machinery.

Conclusion

The contribution of ball screws in the modern machinery is indispensable; it has emerged as an integral component for building modern-day machinery. Ball screw plays a vital role in promoting linear motion, reducing friction, enhancing sustainability, and propagating better movement in complex machinery. As modern technologies tend to evolve and modern technologies come with every passing day, some existing technologies tend to exit and remain unmoved through time.